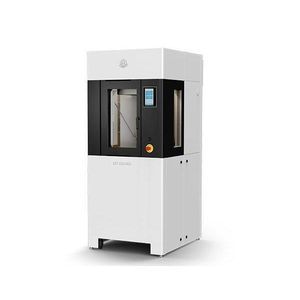

Impresora 3D de materiales plásticos PSLA 270industrialSLAcontinua

Añadir a mis favoritos

Añadir al comparador

Características

- Material de impresión

- de materiales plásticos

- Aplicaciones

- industrial

- Tecnología

- SLA

- Otras características

- continuo

Descripción

Product DetailsThe PSLA 270 combines the best of SLA with the best of light projection for true production. This high-resolution 3D printer merges the speed and production-grade material advantages of Figure 4 light projection technology with the reproducible, high-quality results of SLA.Fast: Dual HD projector-based SLA offers layer curing times up to 5x faster than laser-based technology.Precise: 7-watt high-power projectors deliver first-article success with 90µm pixel resolution, exceptional print quality, and repeatability.Versatile: Compact size with large print volume. Ideal for service bureaus and production applications.Easy to Use: Simple user interface guides you through the end-to-end printing process to maximize uptime and productivity.Easy to Install: Fits through a standard doorway and can be installed in a few hours. Only a standard power outlet is needed.Projection-Based SLA SystemThe PSLA 270 architecture combines the pixel productivity of projection-based technology with the non-contact precision of SLA. Its dual high-resolution projectors offer unmatched pixel efficiency, far surpassing traditional laser systems.First Article Success and PrecisionNo contact or gravity-based distortion. The result is remarkable accuracy, consistency, and part quality regardless of geometry, with a fraction of the support structure required by other solutions.New Hardware ArchitectureVat Design: Roll-in-place vat is precisely located, simplifying material leveling and making material changes easier.Recoater Design: Dual-rail recoating system further improves part quality at higher movement speeds. Precision fixing feature makes material handling fast.Clean Interior: Designed for frequent material changes, with stainless steel covers to minimize maintenance and cleaning time.Material Loading: Add material to the vat via manual pour or automatic resin fill pump, enabling continuous operation without frequent manual intervention.Material Leveling: Offset leveling system dramatically improves leveling performance and reduces overall system complexity.Compatible MaterialsFigure 4 PRO-BLK 10: Production-grade rigid material for production partsFigure 4 Rigid White: Opaque white rigid plastic for productionFigure 4 Rigid Gray: High-contrast gray plastic for long-term use with balanced thermal and mechanical propertiesFigure 4 HI TEMP 300-AMB: Translucent plastic resistant to high temperatures (HDT > 300°C)Figure 4 EGGSHELL-AMB 10: Process-optimized material for sacrificial tools for silicone castingFigure 4 FLEX-BLK 20: Highly stable, durable, and flexible plasticFigure 4 Tough 60C White: White plastic for long-term use with a good combination of impact resistance, elongation, and tensile strengthFigure 4 Tough FR V0 Black: Production-grade, tough, flame-retardant black plastic, UL94 V0Production-Grade ResinsDesigned to work with the Figure 4 range of engineering and production-grade resins, providing printed parts with injection-molded-like quality and best-in-class smoothness. Choose from a growing range of rigid, tough, durable, thermoplastic-like, moldable, heat-resistant, and biocompatible-capable materials in a variety of colors and translucencies. Printed parts exhibit long-term stable mechanical properties against UV and humidity; up to 8 years for indoor use and up to 1.5 years for outdoor exposure (ASTM D4329 and ASTM G194).Piece QualityProduces parts of exceptional quality and precision, a direct result of proprietary pixel blending methods combined with precision projectors and innovative hardware. 3D Systems' image processing software automatically adjusts pixel edges with grayscale scaling techniques, resulting in high-quality, production-grade plastic parts with best-in-class surface quality.Flexible ManufacturingCan deliver true production-level and batch results with all the first-article success and job reliability of vat-based SLA printing. Whether building large individual parts or populating a platform with many small components, performance and output remain consistent and repeatable at a statistically significant level across multiple printers. High-quality, tough material helps ensure long-term durability.Easy Material ChangeFeatures a mobile cart designed to accommodate a variety of vat sizes for better application fit. The vat system is designed to keep the elevator, offsetter, and recoater nested with the resin vat they are used with. The Material Delivery Module (MDM) is also an integral part of the mobile cart, so nothing needs to be cleaned during a material change. Just swap carts, and all necessary components come with it. Precise vat location ensures the smoothest possible material.Flexible DesignDoors and user interface can be flipped to allow the UI to be placed on either side of the machine, enabling the most efficient layout for your space and workflow. The compact frame allows the printer to pass through a standard doorway for easy delivery and installation.ApplicationsDurable end-use plastic partsRapid prototyping and concept modelsShort-run/low-volume plastic part productionJigs and fixturesRapid toolingTool insertsInvestment castingEnvironmentally stable partsMicrofluidicsMedical applications requiring biocompatibility or heat resistanceAdvantagesHigh-performance, same-day partsFirst-article successHigh-resolution printer combining speed and material performance benefitsBridges gap between smaller projection systems and large-frame SLAQuick and easy material changeTrue mid-frame build volumeRoll-in-place vat mounts on printer frameIndustrial-grade durabilityApplication flexibilityTechnical SpecificationsPrintable build volume (xyz): 242 x 265 x 300 mm (9.5 x 10.4 x 11.8 in)Compact printer sizeProjection-based SLA printing with dual 7-watt HD projectorsDual-rail recoating systemAdd material to vat via automatic resin fill pump or manual pourProduction-grade materialsIndustry-leading 3D Sprint software for file preparation and productionCloud connectivity for predictive and fast service with 3D Connect functionality

Catálogos

No hay ningún catálogo disponible para este producto.

Ver todos los catálogos de 3D SystemsFerias

Este distribuidor estará presente en las siguientes ferias

Búsquedas asociadas

- Impresora 3D 3D Systems

- Impresora 3D industrial 3D Systems

- Impresora 3D de materiales plásticos 3D Systems

- Impresora 3D de creación de prototipos 3D Systems

- Impresora 3D de alto rendimiento 3D Systems

- Impresora 3D de alta velocidad

- Impresora 3D de metal 3D Systems

- Impresora 3D ABS

- Impresora 3D de gran formato

- Impresora 3D PLA

- Impresora 3D médica

- Impresora 3D para odontología

- Impresora 3D de resinas

- Impresora 3D de poliamida

- Impresora 3D PETG

- Impresora 3D para la industria aeroespacial

- Impresora 3D SLA 3D Systems

- Impresora 3D para la industria del automóvil

- Impresora 3D de nailon

- Impresora 3D de sinterizado láser

* Los precios no incluyen impuestos, gastos de entrega ni derechos de exportación. Tampoco incluyen gastos de instalación o de puesta en marcha. Los precios se dan a título indicativo y pueden cambiar en función del país, del coste de las materias primas y de los tipos de cambio.