Etiquetadora automática Wraptor A6500de lataswraparounden línea

Añadir a mis favoritos

Añadir al comparador

¿Quiere comprar directamente?

Visite nuestra Shop.

Características

- Especificaciones

- automática

- Usos

- de latas

- Colocación de etiquetas

- wraparound

- Otras características

- en línea

- Cadencia

Máx.: 13 p/min

Mín.: 9 p/min

Descripción

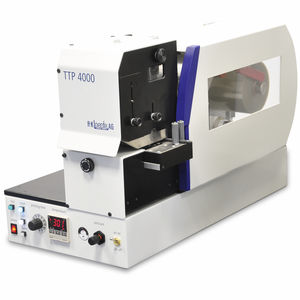

Label marking systems are often used for marking wires or cables that are not suitable for inkjet or hot stamp printing and are therefore subject to a complex processing procedure. However, the processing step of labeling can be fully automated: The in-line wire and cable labeling solution Wraptor A6500 from Brady is compatible with Schleuniger cut-and-strip machines, with which it can be used in-line. Customers can thus fully automate labeling processing steps and, as a result, increase the accuracy and efficiency of their production as well as reduce costs.

Increased efficiency

The Wraptor A6500 is a great tool to control manufacturing cost and enhance identification quality by automatically printing and applying labels. It identifies cables in 5 seconds, eliminates the need to print labels in advance and the time needed to apply them by hand. The Wraptor’s technology enables 300 dpi prints for barcodes, logos and diagrams, and a tight label wrap around the wire, with minimal bubbling or wrinkling.

Benefits

Increases production output by printing and applying wrap-around cable labels in 5 seconds

Easy to operate because it can identify a wide range of cables between 1.52 mm and 15.24 mm diameter via a modern user interface with full color touchscreen

Easy to implement in a variety of production environments thanks to USB ports and Ethernet connectivity

Can be used with Brady Workstation apps to design, print and apply a wide range of labels

Allows saving and processing commonly used labels

Can be integrated with Schleuniger Cut & Strip Machines

Catálogos

No hay ningún catálogo disponible para este producto.

Ver todos los catálogos de Schleuniger* Los precios no incluyen impuestos, gastos de entrega ni derechos de exportación. Tampoco incluyen gastos de instalación o de puesta en marcha. Los precios se dan a título indicativo y pueden cambiar en función del país, del coste de las materias primas y de los tipos de cambio.