- Productos

- Aparato de metrología dimensional

- Proton Products Inc

- Productos

- Catálogos

- News & Trends

- Ferias

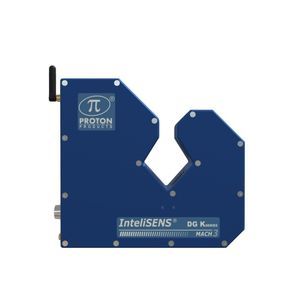

Aparato de metrología dimensional InteliSENS DGk2000-i4 Series

Añadir a mis favoritos

Añadir al comparador

¿Quiere comprar directamente?

Visite nuestra Shop.

Descripción

Product Details Diameter Gauge The InteliSENS® DGk dual-axis diameter gauge does much more than measure diameters. LED and CCD technology, with our specially designed optics, provides ultra-fast and high-precision measurement of diameter and position, analyzing your product's surface in precise detail. This technology has no moving parts, no wear, and no drift. The FPGA processor used in DGk diameter gauges enables ultra-fast measurements: 10,000 scans per second as standard and, optionally, 20,000 scans per second. Additional options add measurement, control, alarm, and product quality reporting functions. Like all Proton i4 products, each gauge features digital and industrial inputs and outputs for easy integration into your production lines. High-resolution precise measurement No moving parts for high reliability and low maintenance Full integration with PLC and measuring equipment Industry 4.0 data communications SMFD defect detection PID controller FFT analysis; SPC; Statistics Analog output Performance Table DGk2015-i4 DGk2030-i4 DGk2060-i4 DGk2120-i4 DGk2200-i4 DGk2300-i4 DGk2400-i4 Minimum diameter 0.2 mm .008″ 0.2 mm .008″ 0.3 mm .012″ 5 mm 0.2″ 5 mm 0.2″ 10 mm 0.39″ 10 mm 0.39″ Maximum diameter 15 mm 5/8″ 30 mm 1 3/16″ 60 mm 2 23/64″ 120 mm 4 23/32″ 180 mm 7 3/32″ 280 mm 11″ 380 mm 14.96″ Accuracy† 1 μm 1 μm ± (3 μm + 0.01% of object diameter) ± (50 μm + 0.05% of object diameter) ± (50 μm + 0.05% of object diameter) ± (50 μm + 0.05% of object diameter) ± (50 μm + 0.05% of object diameter) Resolution 0.01 μm 0.01 μm 0.01 μm 0.01 μm 0.01 μm 0.01 μm 0.01 μm Scan speed 10,000 scans/s (20,000 scans/s with Superfast Scan option) 10,000 scans/s (20,000 scans/s with Superfast Scan option) 10,000 scans/s (20,000 scans/s with Superfast Scan option) 3,000 scans/s 3,000 scans/s 10,000 scans/s 10,000 scans/s †: object centered in the optical gate. Measurement Technology Unlike traditional laser diameter gauges, which use a mechanically scanned laser beam, the InteliSENS® DGK-i4 uses a solid-state technique. An LED light source generates a wide collimated light beam that fully illuminates the measurement area. The shadow generated by an object inserted into this light beam is visualized by a CCD, and the resulting electrical signal is digitally processed to measure the diameter. This solid-state approach offers the following advantages over traditional laser diameter gauges: Higher measurement speed (not limited by mechanical scan time). Greater reliability and MTBF of the gauge as there is no wear from moving parts. No laser precautions required, as a non-laser light source is used. Connectivity Analog speed input 0 -10VDC: Required for Helix Mode, Tolerance Location, and SMFD, Statistics, and PI options. Feedback Diameter Control options. Maximum frequency 250 kHz, max pulses 30V or 50V on two separate inputs. Required for Helix Mode, Tolerance Location, and optional SMFD, Statistics, and PI. Feedback diameter control options. 2 x logic inputs: User-configurable function: Reset; External Alarm 1; External Alarm 2; Line Direction Inversion: 24 VDC 4 x normally open relays: Max 1A / 24 VDC. Gauge OK, Upper Tolerance, Lower Tolerances, Single Measurement Flaw Detection (SMFD) 1 x RS232 / RS422 / RS485: MODBUS RTU; PROTON ASCII code or label; USB via RS232 - USB converter cable; RS485 MODBUS RTU; PROTON ASCII code (not available with PROFIBUS) 1 x CANBUS: Proprietary CAN protocol to connect the CDi4 display interface, including CS5G / via CS1000 1 x iBUS: Connection to a PLC via PROFIBUS, PROFINET, EtherNet/IP [all included: select the one you wish to use]. Data update rate up to 500/sec. Flexible data configuration, Big Endian, Little Endian. 1 x Ethernet: Ethernet Modbus TCP (or 'Ethernet TCP/IP'); Ethernet UDP. OPC UA support: OPC UA 1.03. Connect DGk gauges to your OPC UA data collection system. 1 x Wifi: Wi-Fi for meter configuration and diagnostics. Additional Gauge Head Hardware 3 analog outputs (±10 V) adjustable to X, Y, Z axis output for 2 and 3 axis gauges. Mean diameter, diameter error, ovality, and ovality error. Feedback control monitors the actual measured diameter compared to a preset value and provides a control output signal that can be used to adjust the motor output and keep the product diameter within the preset value. Additional Software for Gauge Heads DGK10k scan option updates the standard gauge to a super-high scan speed, ideal when used with SMFD single measurement flaw detection. Each scan takes only 1 ms to obtain and output a new diameter reading. Maximum, Minimum, Mean, Standard Deviation, Cp, Cpk are collected over a selectable period or duration. Results are updated on the universal SiDi CDi4 display, PCIS software, and can be digitally transmitted. Statistical Process Control (SPC) enhances the feedback control option. Statistical Process Control "measures" Process Capability and automatically adjusts the control setpoint to maximize material savings while maintaining control within upper and lower limits. Fast Fourier Transform (FFT) analyzes diameter data for periodicity. Provides amplitude vs. frequency data and a graphical representation on the universal SiDi CDi4 display or PCIS software. Single Measurement Flaw Detection (SMFD) analyzes each individual measurement and compares it to the current mean. If an individual measurement is above the current mean and above or below a threshold value, a flaw is detected. Electrical and Operating Requirements Power supply 18-30 VDC Power consumption 30 watts Operating temperature 5°C - 45°C (41-113°F) Environmental protection IP 65 Power supply 100 - 240 VAC (50 - 60 Hz) Power consumption 100 watts Operating temperature 5°C - 45°C (41-113°F) Environmental protection IP 65 Size and Weight DGk2015-i4 Height 230 mm (9.1") Width 248 mm (9.8") Length 64 mm (2.5") Weight 3.4 kg (7.5 lbs) DGk2030-i4 Height 300 mm (11.8") Width 310 mm (12.2") Length 56 mm (2.2") Weight 5 kg (11 lbs) DGk2060-i4 Height 475 mm (18.7") Width 435 mm (17.1") Length 66 mm (2.6") Weight 8 kg (17.6 lbs) DGk2120-i4 / DGk2200-i4 Height 1316 mm (51.8") Width 755.7 mm (29.75") Length 124 mm (4.88") DGk2300-i4 / DGk2400-i4 Height 1680 mm (66.1″) Width 226 mm (8.9″) Length 1500 mm (59″) Key Features / Technical Specifications Dual-axis diameter measurement with LED and CCD technology Ultra-fast, high-precision measurement No moving parts, no wear, no drift FPGA processor for up to 20,000 scans/sec Industry 4.0 ready: digital and industrial I/O Multiple connectivity options: analog, digital, RS232/422/485, CANBUS, iBUS, Ethernet, Wi-Fi Environmental protection: IP65 Wide range of models for different diameter ranges Optional advanced software: FFT, SPC, SMFD, statistics Power supply: 18-30 VDC or 100-240 VAC Operating temperature: 5°C - 45°C

Otros productos de Proton Products Inc

Medición de diámetros

* Los precios no incluyen impuestos, gastos de entrega ni derechos de exportación. Tampoco incluyen gastos de instalación o de puesta en marcha. Los precios se dan a título indicativo y pueden cambiar en función del país, del coste de las materias primas y de los tipos de cambio.