- Productos

- Aparato de metrología dimensional

- Proton Products Inc

- Productos

- Catálogos

- News & Trends

- Ferias

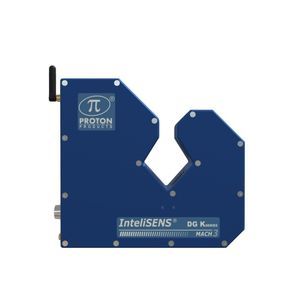

Aparato de metrología dimensional DG1000

Añadir a mis favoritos

Añadir al comparador

¿Quiere comprar directamente?

Visite nuestra Shop.

Descripción

Non-contact Diameter MeasurementInteliSENS® DG Series Precision Laser Scanning Gauges are designed for use in a wide range of processes and applications. Measure diameters, multiple diameters, height, width, separation, hot products, or soft products using a range of devices and software applications. The DG Series of InteliSENS gauges can be used to measure moving products such as hoses, tubes, pipes, paper tubes, steel bars, wires, and cables during the manufacturing process. Alternatively, the DG Series gauges can be used to measure discrete static or moving parts during quality inspection processes.InteliSENS DG Series gauges are Smart Sensors for use in your Industry 4.0 environment. Access all measurement and diagnostic data directly from a PLC, PC, or mobile device via wired or wireless connectivity.Accurate, linear, repeatableMulti-segment measurementIn-line or off-line applicationsWired and wireless connectivityStandalone or integrated deviceIndustry 4.0 smart sensorPerformanceDG1030DG1060DG1130Minimum diameter0.1 mm3.9 mil0.4 mm16 mil0.5 mm20 milMaximum diameter25 mm5/8″55 mm1 3/16″125 mm2 23/64″Scanning speed600 scans per secondResolution0.0001 mm, 0.000004 inMeasurement modeDiameter, separation, edgeUnitsmm, inchMeasurement PrincipleThe InteliSENS® DG series diameter gauges from Proton Products rapidly scan a laser beam across the object being measured. The laser beam is focused by a receiver lens onto a photodiode, and the electrical signal is digitally processed by a Proton-designed FPGA processor. The time during which the object obscures the laser beam is directly proportional to the object's diameter.ConnectivityAnalog input 0 -10VDC: Required for Helix Mode, Tolerance Location, and optional SMFD and PI feedback diameter controlPulse input: Max frequency 250 kHz, max pulses 30V or 50V on two separate inputs. Required for Helix Mode, Tolerance Location, and optional SMFD and PI feedback diameter controlMax voltage 24Vdc, current 1A: OK gauge, Upper Tolerance, Lower Tolerances, Single Measurement Fault Detection (SMFD)RS232 MODBUS RTU, PROTON ASCII code or Label Printer. USB via RS232 - USB converter cable. RS485 MODBUS RTU, PROTON ASCII code (Not available with PROFIBUS)Connects to Proton Products Cdi displayPLC connection via PROFIBUS, PROFINET, or EtherNet I/P, data update rate up to 500/sec. Flexible data configuration, Big Endian, Little EndianEthernet selectable between OPC-UA and ModbusConnect to a PC or mobile device via WiFi 2.4G and use the Proton Products Gauge App available for iOS and Android. Ideal for gauge setup and diagnosticsCaliper Head Additional Hardware3 adjustable analog outputs (±10V) for X, Y, Z axis output for 2 and 3 axis gauges. Mean diameter, diameter error, ovality, and ovality errorFeedback control monitors the actual measured diameter compared to a preset value and provides a control output signal that can be used to adjust the motor output and maintain the product diameter within the preset valueMaximum, Minimum, Mean, Standard Deviation, Cp, Cpk are collected over a selectable time or duration. Results are updated on the universal SiDi CD14 display, PGIS software, and can be digitally transmittedStatistical Process Control (SPC) enhances the feedback control option. SPC measures Process Capability and automatically adjusts the control setpoint to maximize material savings while maintaining control within upper and lower limitsFast Fourier Transform (FFT) analyzes diameter data for periodicity. Provides amplitude data as a function of frequency and a graphical representation on the universal SiDi CD14 display or PCIS softwareSingle Measurement Fault Detection (SMFD) analyzes each individual measurement and compares it to the current mean. If an individual measurement is above the current mean and exceeds a threshold value, a fault is detectedElectrical and Operating RequirementsPower supply100 - 240 VACPower consumption150WOperating temperature5°C - 45°C (41-113°F)Environmental protectionIP 54Size and WeightDG1030-i4Height (excluding Wi-Fi antenna):198 mm (7.79")Height (with CDi4 attached):363 mm (14.3 in)Width290 mmThickness63 mmWeight3 kg (6.61 lbs)DG1060-i4Height (excluding Wi-Fi antenna)209 mm (8.23")Height (with CDi4 attached):374 mmWidth550 mmThickness65 mmWeight7 kg (15.4 lbs)DG1130-i4Height281 mmWidth734 mmThickness69 mmWeight12 kg (26.45 lbs)Product Category: Diameter MeasurementProduct Type: Laser Scanning Diameter GaugeBrand: Proton ProductsTechnical Specifications / FeaturesNon-contact laser scanning measurementIndustry 4.0 smart sensorWired and wireless connectivity (Ethernet, WiFi, RS232, RS485, PROFIBUS, PROFINET, EtherNet I/P, OPC-UA, Modbus)Measurement range: DG1030: 0.1–25 mm, DG1060: 0.4–55 mm, DG1130: 0.5–125 mmResolution: 0.0001 mmScanning speed: 600 scans/secEnvironmental protection: IP54Power supply: 100–240 VAC, 150WOperating temperature: 5–45°CStatistical process control, FFT analysis, feedback controlMultiple analog outputs, digital outputs

Otros productos de Proton Products Inc

Medición de diámetros

* Los precios no incluyen impuestos, gastos de entrega ni derechos de exportación. Tampoco incluyen gastos de instalación o de puesta en marcha. Los precios se dan a título indicativo y pueden cambiar en función del país, del coste de las materias primas y de los tipos de cambio.