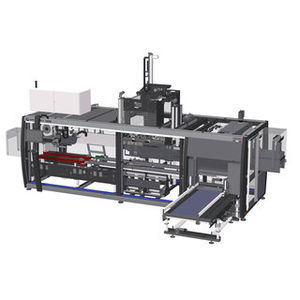

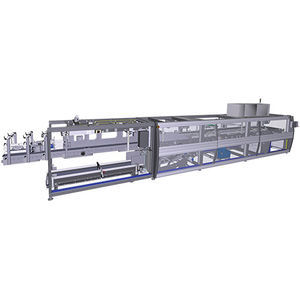

Encartonadora envolvente WP 1000 ERGONde carga superiorpara la industria cosméticapara la industria agroalimentaria

Añadir a mis favoritos

Añadir al comparador

¿Quiere comprar directamente?

Visite nuestra Shop.

Características

- Tipo

- de carga superior, envolvente

- Aplicaciones

- para la industria farmacéutica, para la industria agroalimentaria, para la industria cosmética

- Otras características

- automática

- Cadencia

100 p/min

Descripción

The WP ERGON series consists of automatic machines for packing plastic, metal, cardboard, or glass containers in corrugated cardboard boxes and/or trays without film, with outputs of up to 100 packs per minute, depending on the machine model and the type of product to be packed.The achievable formats vary according to the shape, capacity, and dimensions of the containers; generally, the most demanded configurations in the market are: 2x3, 3x4, and 4x6.The new WP 1000 ERGON stands out for its innovative automatic guide adjustment system, located at the machine's entry, which significantly reduces downtime and ensures consistent quality and efficiency during format changes.The packer is also equipped with a top-loading product separation system, ensuring high operational efficiency.The grouping of products is smooth, fast, and reliable, thanks to two opposing bars that release the set of products according to the selected format.Format changes are equally simple: operators only need to remove the plates with separation pins from the upper bars and replace them with those suitable for the new format.WP 1000Speed (PPM)100PackagesTray onlyWrap-around boxTracks1Operation Steps:At the machine's entry area, a special group of guides correctly channels the loose containers, driven by a conveyor belt with low-friction thermoplastic chains. In the pack formation area, containers are continuously grouped into the required format by electronically synchronized paddles.The new Easy-Load system automatically loads the cartons into the machine's carton magazine. The new loading device consists of a series of motorized mesh conveyors where the operator easily positions the cartons in uniform horizontal stacks.The corrugated cardboard is taken from the magazine by a newly designed picker equipped with vacuum suction cups, travels up the carton ramp, and is positioned under the moving product group with the short side as the leading edge. The box/tray former operates continuously with a wrap-around system.Subsequently, the flap folding devices first fold the side flaps and then the upper/lower flaps, both at the front and rear. Hot glue sealing ensures the package is perfectly sealed.At the machine's exit, the box walls are pressed by special guides.Technical Features:Supporting structure of sandblasted and powder-painted steelSliding protective doors in rounded anodized aluminum, with all (low energy consumption) motors positioned outside the mechanical groups they drive. The door closing system is equipped with a deceleration device for smooth final closure.Absence of gearmotors and predominant use of ICOS brushless motors with integrated digital servo-drive (controller) in the motorContinuous product grouping device, with electronically synchronized plastic fingersLifetime-lubricated bearingsEntry conveyor with low-friction thermoplastic chains and motorized oscillating channeling guide systemCarton magazine located under the entry conveyor, in an easily accessible position (models P and T)Cam carton dispenser equipped with vacuum suction cupsMachine electrical cabinet equipped with air conditionerInteractive touchscreen with intuitive graphicsMain Advantages:Modular design: SMI machines are designed according to advanced modular assembly principles and interchangeability of mechanical and electronic components, reducing downtime during maintenance and optimizing spare parts use.Operational flexibility: These packers can pack a wide range of products in many different configurations, meeting current and future user needs. Each machine can be equipped with additional devices for increased functionality and high customization of the final package.Motors connected directly to transmission shafts, reducing maintenance, energy dissipation, and noise.Continuous pack formation system ensures a smooth production process, protecting containers from shocks and ensuring higher reliability, better package quality, and reduced mechanical wear.Thermoplastic separation fingers in the pack formation area last longer than metal ones, reduce machine noise, and preserve the integrity of delicate containers (like glass) and labels.Easy and economical maintenance: Rounded protective doors provide more space in the machine, allowing motors to be installed outside the mechanical units, facilitating maintenance activities.Innovative shapes: All SMI cartoners can produce hexagonal or octagonal boxes from microflute/miniflute corrugated cardboard, suitable for more sophisticated graphic printing processes.Perfect squaring system: Fixed guides at the machine's exit keep the box walls pressed, ensuring perfect and lasting squaring, unlike rotary chain pressing systems.User-friendly human-machine interface: The POSYC® control panel, running the length of the machine, allows even less experienced operators to use the packaging machine easily and efficiently, thanks to a very simple graphical interface, touch screen, and advanced real-time diagnostic/support functions.Accessories:Easy-Load: The innovative “Easy-Load” system allows automatic loading of the carton magazine and offers significant operational and functional advantages: the horizontally stacked die-cut cartons can be easily loaded by the operator, as the magazine feed belt is at the same working height as the packer's entry belt. The system is fully automated with dedicated sensors and motorized conveyor belts, handling a wide range of carton thicknesses (0.5 mm to 5 mm).PID SBP®: Allows the insertion of preformed pressed cardboard separators inside boxes to protect fragile products (e.g., glass containers) and labels from damage. This device can be installed on WP cartoners and combined CM machines. Compared to traditional methods, it reduces separator acquisition costs by almost 20% and storage volume by at least 60%, maintains standard cartoner dimensions, speeds up insertion and loading, and reduces sensitivity to humidity and climate variations. The PID SBP® and its magazine are positioned at the machine entry, above the pack formation area, with a maximum speed of 40 packs/min (1 head) or 60 packs/min (2 heads).Technical Specifications:Speed: up to 100 packs per minutePackage types: Tray only, Wrap-around boxTracks: 1Structure: Sandblasted and powder-painted steelProtective doors: Rounded anodized aluminumMotors: ICOS brushless with integrated digital servo-driveGrouping device: Continuous, with plastic fingersBearings: Lifetime-lubricatedEntry conveyor: Thermoplastic chains, motorized guidesCarton magazine: Under entry conveyor, easily accessibleCarton dispenser: Cam, vacuum suction cupsElectrical cabinet: With air conditionerTouchscreen: Interactive, intuitive graphics

Catálogos

No hay ningún catálogo disponible para este producto.

Ver todos los catálogos de SMI GroupFerias

Este distribuidor estará presente en las siguientes ferias

Búsquedas asociadas

- Máquina de acondicionamiento

- Máquina de llenado automática

- Máquina de acondicionamiento automática

- Llenadora de líquidos

- Máquina de embalaje para la industria agroalimentaria

- Paletizador

- Máquina de llenado volumétrica

- Retractiladora SMI

- Retractiladora automática SMI

- Línea de embalaje

- Paletizador automatizado

- Encajadora SMI

- Encajadora automática SMI

- Paletizador robotizado

- Línea de embalaje automática

- Máquina de embalaje para la industria farmacéutica

- Máquina de llenado compacta

- Encartonadora

- Máquina de embalaje de gran velocidad

- Paletizador para cajas

* Los precios no incluyen impuestos, gastos de entrega ni derechos de exportación. Tampoco incluyen gastos de instalación o de puesta en marcha. Los precios se dan a título indicativo y pueden cambiar en función del país, del coste de las materias primas y de los tipos de cambio.