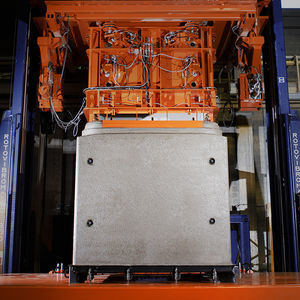

Máquina para fabricar para productos de hormigón Vibromaxautomáticopara obra de construcción

Añadir a mis favoritos

Añadir al comparador

Características

- Producto acabado

- para productos de hormigón

- Otras características

- automático

- Sector

- para obra de construcción

Descripción

Fully automatic machine for production by vibrocompression, with direct demolding of products with heights between 1,000 mm and 3,000 mm, especially suitable for large-sized manufactured products.PresentationFully automatic machine for the production by vibrocompression, with direct demolding of a wide variety of concrete products. It is especially suitable for the automatic production of large-sized manufactured products.The machine can produce, depending on the different models, elements with diameters ranging from 300 mm to 3,000 mm (rectangular pipes up to 3,000 mm x 3,000 mm), with a variable height between 250 mm and 3,000 mm, in single mode (multiple production can also be provided on request).Technical FeaturesThe machine can be equipped with a quick hydraulic mold change system, simple and fast to use, allowing daily mold changes in less than 1.5 hours (also, there is no longer a need to adjust the internal mold, external molds, and pressers after production change).Concrete feeding is fully automatic: the conveyor belt is combined with a special epicyclic spreader, with 4 rotating elements, which distributes the concrete in minimal time, even to the most peripheral points; this solution is very effective in the production of rectangular pipes and large-sized manufactured products.Thanks to other additional components, Vibromax is a highly functional machine: vibration regulation, either mechanical or electronic, via inverter; the loading hopper can be inspected for cleaning operations; automatic expulsion of prefabricated products at the end of the cycle by motorized trailer, with possible subsequent movements and storage.The system can be complemented with automatic feeding of the bases (which will be frontal) and/or cleaning and greasing of the bases, with the introduction of joints, with automatic overhead movement. These advantages further streamline the production cycle, reducing the necessary personnel.The general management and control of the machine are carried out via PC with the Vicom system, with synoptic panels for machine status and anomaly control, equipped with modules for remote assistance, with the possibility of remote production management (Industry 4.0).Products that can be made:Circular pipesCircular pipes with flat baseUnreinforced pipesReinforced pipes with rigid reinforcementReinforced pipes with fibersDrainage pipesJacking pipesPipes with male-male connectorsRectangular and ovoid pipesWell bottoms (inspection)Extensions and terminal conesMonolithic cones for wells (inspection)Flat coversExtensions for wells (inspections)Pipes with branchesRoad discharge wellsDrainage channelsSpecial manufactured products in general, made to order for specific customer requests, with any type of jointAdvantagesHigh productionFlexibility (can produce a wide range of products; ideal machine for automatic production of large-sized manufactured products)Reduced personnel requiredHigh product quality, guaranteed by automatic electronic regulation via vibration (with vibrator mounted inside the mold) and concrete feedingVery fast mold change (reduced times allow mold change, on the same day, for a possible second work shift), without the need to adjust the mold after the changeComplete machine control via PC with Vicom system, with the possibility of remote production management (Industry 4.0)Technical Specifications / FeaturesProduction by vibrocompressionDirect demoldingProduct height: 1,000 mm to 3,000 mmProduct diameter: 300 mm to 3,000 mm (rectangular up to 3,000 mm x 3,000 mm)Automatic concrete feedingQuick hydraulic mold change systemPC-based control with remote management capabilitiesSuitable for large-sized concrete products

VÍDEO

Catálogos

No hay ningún catálogo disponible para este producto.

Ver todos los catálogos de Colle S.p.a.* Los precios no incluyen impuestos, gastos de entrega ni derechos de exportación. Tampoco incluyen gastos de instalación o de puesta en marcha. Los precios se dan a título indicativo y pueden cambiar en función del país, del coste de las materias primas y de los tipos de cambio.