- Máquinas de Producción

- Plasturgia

- Colle S.p.a.

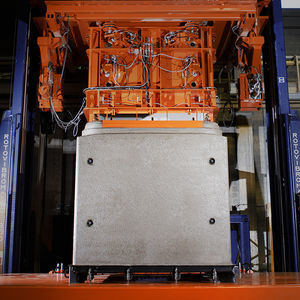

Moldeo por compresión para el sector de la construcción Turbomaster series

Añadir a mis favoritos

Añadir al comparador

Características

- Aplicaciones

- para el sector de la construcción

Descripción

Completely automatic machine for the radial compression production of manufactured products with heights ranging from 1,000 mm to 4,000 mm.

Product Overview:

Completely automatic machine for the radial compression production of circular concrete pipes, with any type of joint. The machine can produce, depending on the different models, elements with diameters ranging from 300 mm to 1,600 mm, with a variable height from 1,000 mm to 4,000 mm, in two modes: with a single mold or with a double mold.

Technical Features:

- The machine can be equipped with a quick hydraulic mold change system, simple and fast to use, allowing daily quick changes of molds in a very short time.

- Height control of the precast elements is provided.

- Turbomaster uses the moving piston technology along the entire length of the manufactured product, with a rotating end (piston) equipped with spreaders for concrete distribution. The piston, electronically controlled, interacts with the concrete feeding device.

- The compacting rollers rotate in the opposite direction to the smoothers (allowing reinforcements not to twist); the system guarantees the production of pipes of total quality, without defects and perfectly smooth.

- The concrete feeding is fully automatic. The conveyor belt supplies the concrete at the central point of the mold, always calibrating the right amount; this aspect is crucial to maximize filling speed and compaction quality.

- The system can be complemented with automatic movement and storage of the precast elements, with automatic cleaning and movement of the bases, and with the introduction of joints. These advantages further streamline the production cycle, reducing the necessary personnel.

- The general management and control of the machine are carried out via the Vicom PC system, with synoptic panels for machine status and anomaly control, equipped with modules for remote assistance, with the possibility of remote production management (Industry 4.0).

Products that can be manufactured:

- Circular pipes

- Circular pipes with laying surface

- Non-reinforced pipes

- Reinforced pipes with rigid reinforcement

- Reinforced pipes with fibers

- Drainage pipes

- Pipes with male-male connectors

- Extensions for wells

- Manufactured products with any type of joint

Advantages:

- High production output

- Low noise level throughout the production cycle

- Reduced necessary personnel

- High product quality, guaranteed by the automatic electronic regulation of the concrete feeding device, with the rising piston technology, with smoothers and compacting rollers, and with integrated rotating spreaders

- Very fast mold change (reduced times allow mold change, on the same day, for a possible second work shift), without the need to adjust the mold after the change

- Complete machine control via Vicom PC system, with the possibility of remote production management (Industry 4.0)

Technical Data Sheet:

MACHINE | PIPES | PIPE LENGTH

--- | --- | ---

TURBOMASTER 30/60 | 30 cm – 60 cm | H 100 – 400 cm

TURBOMASTER 30/125 | 30 cm – 125 cm | H 100 – 400 cm

TURBOMASTER 30/160 | 30 cm – 160 cm | H 100 – 400 cm

- Completely automatic machine for radial compression production

- Production of circular concrete pipes with any type of joint

- Diameters from 300 mm to 1,600 mm

- Heights from 1,000 mm to 4,000 mm

- Single or double mold operation

- Quick hydraulic mold change system

- Automatic height control

- Moving piston technology with rotating spreaders

- Automatic concrete feeding

- Automatic movement and storage of precast elements

- Remote management and Industry 4.0 compatibility

Catálogos

No hay ningún catálogo disponible para este producto.

Ver todos los catálogos de Colle S.p.a.* Los precios no incluyen impuestos, gastos de entrega ni derechos de exportación. Tampoco incluyen gastos de instalación o de puesta en marcha. Los precios se dan a título indicativo y pueden cambiar en función del país, del coste de las materias primas y de los tipos de cambio.