Máquina para fabricar para la reparación de canalizaciones de hormigón Bimatic seriesautomáticopara obra de construcción

Añadir a mis favoritos

Añadir al comparador

Características

- Producto acabado

- para la reparación de canalizaciones de hormigón

- Otras características

- automático

- Sector

- para obra de construcción

Descripción

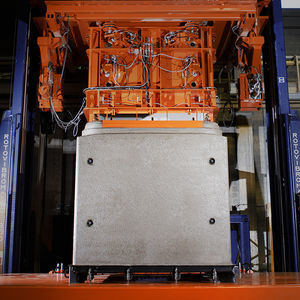

Fully automatic machine for the production of 'off-ground' concrete pipes by vibrocompression, with direct demolding of products with heights between 2,000 mm and 3,000 mm.PresentationFully automatic machine for the production of concrete pipes by vibrocompression, with direct demolding.Bimatic operates off the ground with complete soundproofing installation; it uses the technology of movable cores along the entire length of the piece, with a head equipped with a rotating spreader for concrete distribution.The machine can produce, depending on the different models, elements with diameters ranging from 300 mm to 1,600 mm and variable heights between 2,000 mm and 3,000 mm, thanks to the mobile prefabricated plate, which allows supporting the bottom at any height, ensuring at the same time the fixation in the outer mold. Production can be in single, double, or triple mode, with the possibility of mixed productions.Technical FeaturesThe machine can be equipped with a hydraulic quick-change system for molds, simple and fast to use, allowing daily mold changes in less than 1.5 hours (also, internal mold, external molds, and pressers adjustment is no longer necessary after production change).System available for precise height management of prefabricated products, within a set tolerance. Concrete feeding is fully automatic: the independently driven feeding belts supply concrete to the central point of each mold, always calibrating the right amount, in sync with the rotating spreaders mounted on the heads of the inner cores; all this maximizes filling speed and ensures compaction quality, also facilitating multiple productions of two or three prefabricated products of different diameters.Other features make Bimatic a very versatile and functional machine: internal pipe surface smoothing system, mechanical and electronic vibration adjustment via inverter, and an inspectable loading hopper for cleaning operations.The system can be complemented with automatic bottom feeding (from the rear) and/or bottom cleaning and greasing, with the introduction of joints, with automatic overhead movement. These advantages further streamline the production cycle, reducing the necessary personnel.General management and control of the machine are carried out via PC with Vicom system, with synoptic panels for machine status and anomaly control, equipped with modules for remote assistance, with the possibility of remote production management (Industry 4.0).Products that can be made:Circular pipesCircular pipes with flat baseNon-reinforced pipesReinforced pipes with rigid reinforcementReinforced pipes with fibersDrainage pipesPipes with male-male connectorsJacking pipesProducts manufacturable with any type of jointAdvantagesHigh productionReduced required personnelHigh product quality, guaranteed by automatic electronic vibration regulation (with vibrator mounted inside the mold) and concrete feeding, with rising core technology and built-in spreaderOptimal independent management for mixed productionsVery fast mold change (reduced times allow mold change on the same day for a possible second work shift), without the need to adjust the mold after the changeComplete machine control via PC with Vicom system, with the possibility of remote production management (Industry 4.0)Technical Data SheetMachinePipes (diameter from cm to cm)Pipe lengthBIMATIC 30/12030 cm – 120 cmH 200 – 250 – 300 cmBIMATIC 30/16030 cm – 160 cmH 200 – 250 – 300 cmNumber of pipes per cycleD 300D 400D 500D 600D 700D 800D 900D 1000D 1200D 1400D 1600BIMATIC 30/120 N222211111--BIMATIC 30/120 T333222111--BIMATIC 30/160 N22221111111BIMATIC 30/160 T33322211111Technical Specifications / FeaturesAutomatic vibrocompression productionDirect demoldingDiameter range: 300 mm to 1,600 mmHeight range: 2,000 mm to 3,000 mmProduction modes: single, double, triple, mixedHydraulic quick-change moldsAutomatic concrete feedingInternal surface smoothing systemMechanical/electronic vibration adjustmentPC-based control with remote management (Industry 4.0)

Catálogos

No hay ningún catálogo disponible para este producto.

Ver todos los catálogos de Colle S.p.a.* Los precios no incluyen impuestos, gastos de entrega ni derechos de exportación. Tampoco incluyen gastos de instalación o de puesta en marcha. Los precios se dan a título indicativo y pueden cambiar en función del país, del coste de las materias primas y de los tipos de cambio.