- Mecánica - Transmisión de potencia

- Transmisión Mecánica

- Reductor planetario

- Shanghai Siheng Motor Co., Ltd

- Productos

- Catálogos

- News & Trends

- Ferias

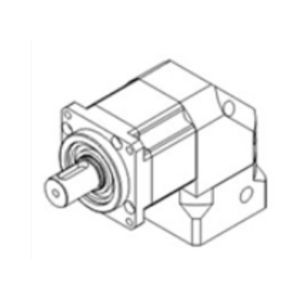

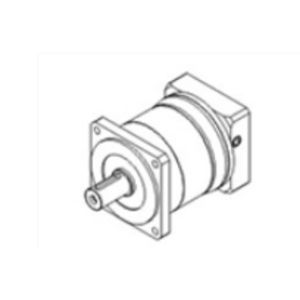

Reductor planetario WPF60 seriesangularcon eje huecode precisión

Añadir a mis favoritos

Añadir al comparador

Características

- Tipo

- planetario

- Orientación de los ejes

- angular

- Tipo de eje

- con eje hueco

- Rendimiento

- de precisión

- Otras características

- de grandes dimensiones

- Velocidad de rotación

Mín.: 3.000 rpm

(18.849,56 rad.min-1)Máx.: 8.000 rpm

(50.265,48 rad.min-1)- Potencia

400 W

(0,54 hp)- Peso

2 kg, 2,3 kg, 2,6 kg

(4,41 lb, 5,07 lb, 5,73 lb)

Descripción

The planetary output support of the reducer adopts an integrated nut to eliminate axial play design. The front and rear bearings are distributed over a large space within the integral housing body, forming a super-strong integrated structure to ensure high torsional rigidity, super-strong radial load capacity, and excellent axial load capacity. A one-time processing and finishing process is adopted to ensure extremely high coaxiality.Outline Dimension Drawing of the ReducerMain Technical ParametersLevelFirst stageSecond stageThird stageReduction ratio3/4/5/7/1012/16/20/25/28/35/40/50/7080/100/125/140/175/200/250/700/1000Body length150.5166.5182.5Maximum radial force400N500N800NMaximum axial force300N390N700NFull load efficiency≥94%≥92%≥88%Weight2.0kg2.3kg2.6kgService life≥20000h≥20000h≥20000hRated input speed3000rpm3000rpm3000rpmMaximum input speed8000rpm8000rpm8000rpmMotor power400W400W400WGear precision grade6 GB/T10095 – 20086 GB/T10095 – 20086 GB/T10095 – 2008Operating temperature–25° ~ +90°–25° ~ +90°–25° ~ +90°Protection gradeIP65IP65IP65Lubrication methodLong-term acting lubricationLong-term acting lubricationLong-term acting lubricationInstallation methodFlangeFlangeFlangeTechnical Specifications / FeaturesIntegrated nut eliminates axial playHigh torsional rigidity and load capacitySuper-strong radial and axial load capacityHigh coaxiality due to one-time processingMultiple reduction ratios availableIP65 protection gradeLong service life (≥20000h)Rated input speed: 3000rpm, max input speed: 8000rpmMotor power: 400WFlange installation

Otros productos de Shanghai Siheng Motor Co., Ltd

Caja de cambios

Búsquedas asociadas

- Reductor

- Reductor epicicloidal

- Reductor concéntrica

- Reductor de precisión

- Reductor angular

- Reductor de tren de engranajes

- Reductor con eje hueco

- Reductor de eje

- Reductor de alta eficacia

- Reductor con brida

- Reductor de alta precisión

- Reductor de montaje en brida

- Reductor de alta calidad

- Servorreductor

- Reductor de grandes dimensiones

- Reductor resistente al agua

- Reductor IP65

- Servorreductor planetario

- Servorreductor con eje macizo

- Servorreductor coaxial

* Los precios no incluyen impuestos, gastos de entrega ni derechos de exportación. Tampoco incluyen gastos de instalación o de puesta en marcha. Los precios se dan a título indicativo y pueden cambiar en función del país, del coste de las materias primas y de los tipos de cambio.